To push the boundaries of what is possible in healthcare and life sciences, each spark of an idea requires the right support team behind it. As a leading contract manufacturer, Comar Medical complements your team’s capabilities so you can bring high-impact solutions to market.

Talk with Our ExpertsDiagnostic consumables that enable the detection of disease and medical conditions at clinical labs or points of care.

Explore Diagnostics ManufacturingPrecision-molded components, assemblies, and finished devices that perform as designed in mission-critical hospital and ambulatory scenarios.

Explore Medical Device ManufacturingComplex components and devices for the professional and patient-controlled administration of medications that extend and improve lives.

Explore Drug Delivery Manufacturing

Our design and prototyping capabilities, coupled with our production and assembly expertise, allow us to offer creative and innovative medical manufacturing solutions that accelerate time to market, reduce costs, and minimize risk.

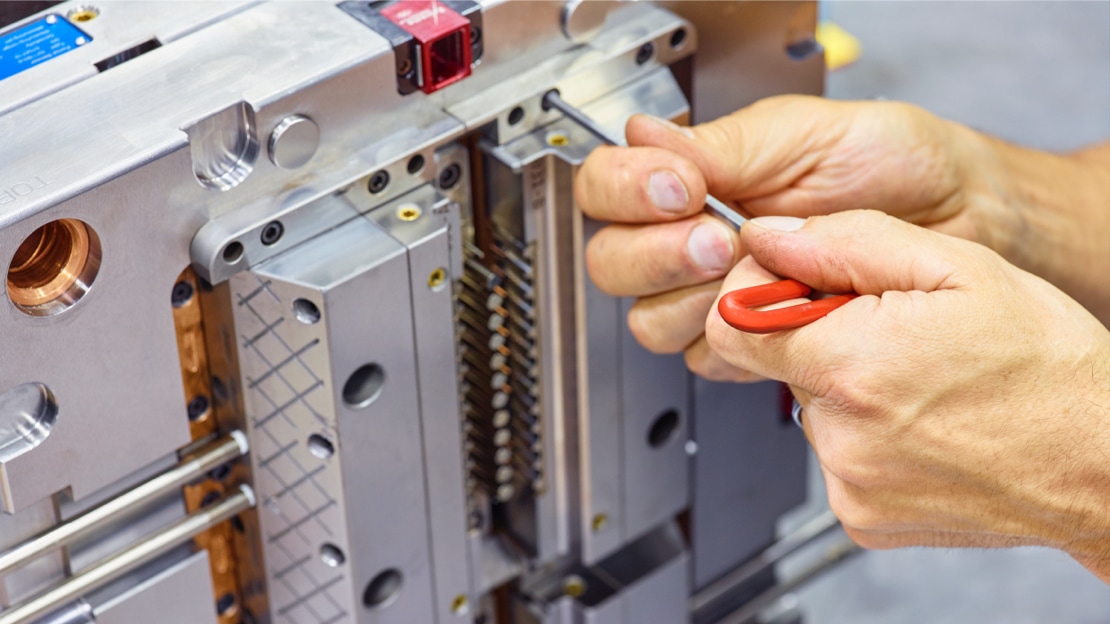

We embrace industry-leading technology with an RJG eDart® system on every single injection molding press to control and monitor the process and ensure the highest quality, service, and value.

Our eleven ISO-Certified Class 7 and 8 cleanrooms and white rooms house molding, automated assembly, and finished packaging capabilities in dedicated and tightly integrated production cells, with room to expand.

Every project we take on is strategic and not a number. If your scope or direction changes, our size enables us to adjust our approach and resources quickly and decisively to your evolving needs while maintaining speed and quality.

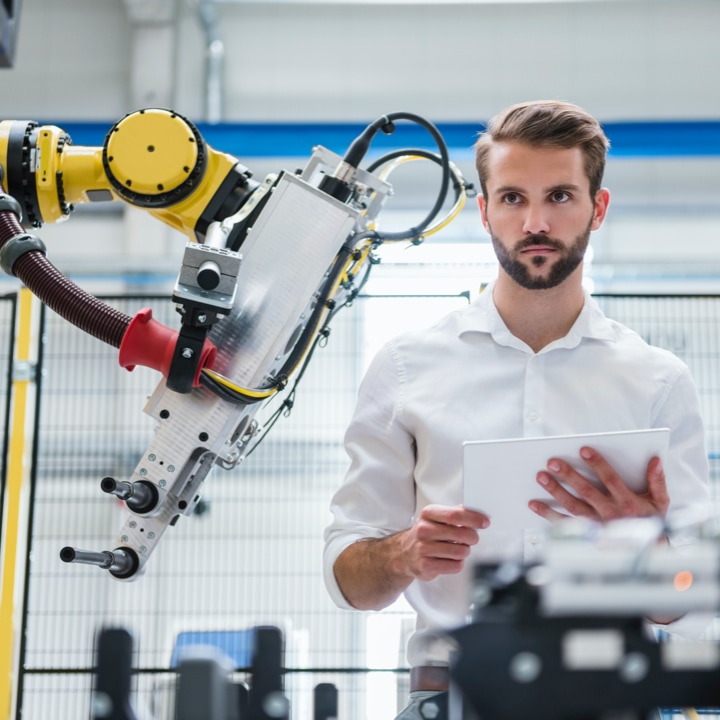

Our engineers are experts in implementing current best practices and exceeding standards. We invest heavily in our teams and equipment so that your results are as advanced as our capabilities.

Through our Innovation & Design Centers, we become an extension of your new product innovation team to help accelerate your time-to-market, reduce your costs, and minimize your risk.

We manufacture with a state-of-the-art platform of mixed molding technologies and embrace scientific molding principles to ensure our processes and controls surpass conventional standards.

Our expertise in robust secondary processes ranging from manual through to high-speed, fully-automated assembly gives us the flexibility to reliably produce sub-assemblies and finished devices for projects of every size, scope, and complexity.

Quality is core to who we are and what we do. We strive to provide products that are flawless in their intended use and “right the first time,” raising the bar on expectations.

Our comprehensive transfer process ensures supply continuity for tooling and equipment transfers of any size, while targeting lead time reduction, increased quality and part-to-part consistency.

Learn More