Our expertise in robust secondary processes, ranging from manual to high-speed fully automated assembly, gives us the flexibility to reliably produce subassemblies and finished devices for projects of every size, scope, and complexity.

Contact UsOur engineers and automation specialists combine their expertise with our post-molding capabilities to produce high-quality, cost-effective parts, components, and devices. We aggressively pursue the newest equipment and techniques so that every solution we propose is unconstrained by technical limitations. Leveraging our competency from manual to fully automated assembly, you can partner with us as a single-source supplier with no need to transfer to a new supplier when you are ready to scale up production.

Our manual assembly capabilities enable us to provide customers with a range of solutions, from subassemblies to finished devices. The manual assembly of components and devices allows you to reduce risk during design, development, and process verification and is most effective when implemented as support for your prelaunch or early-stage low-volume needs, prior to scaling up. It is also well suited to devices with specific geometries that do not lend themselves well to automation.

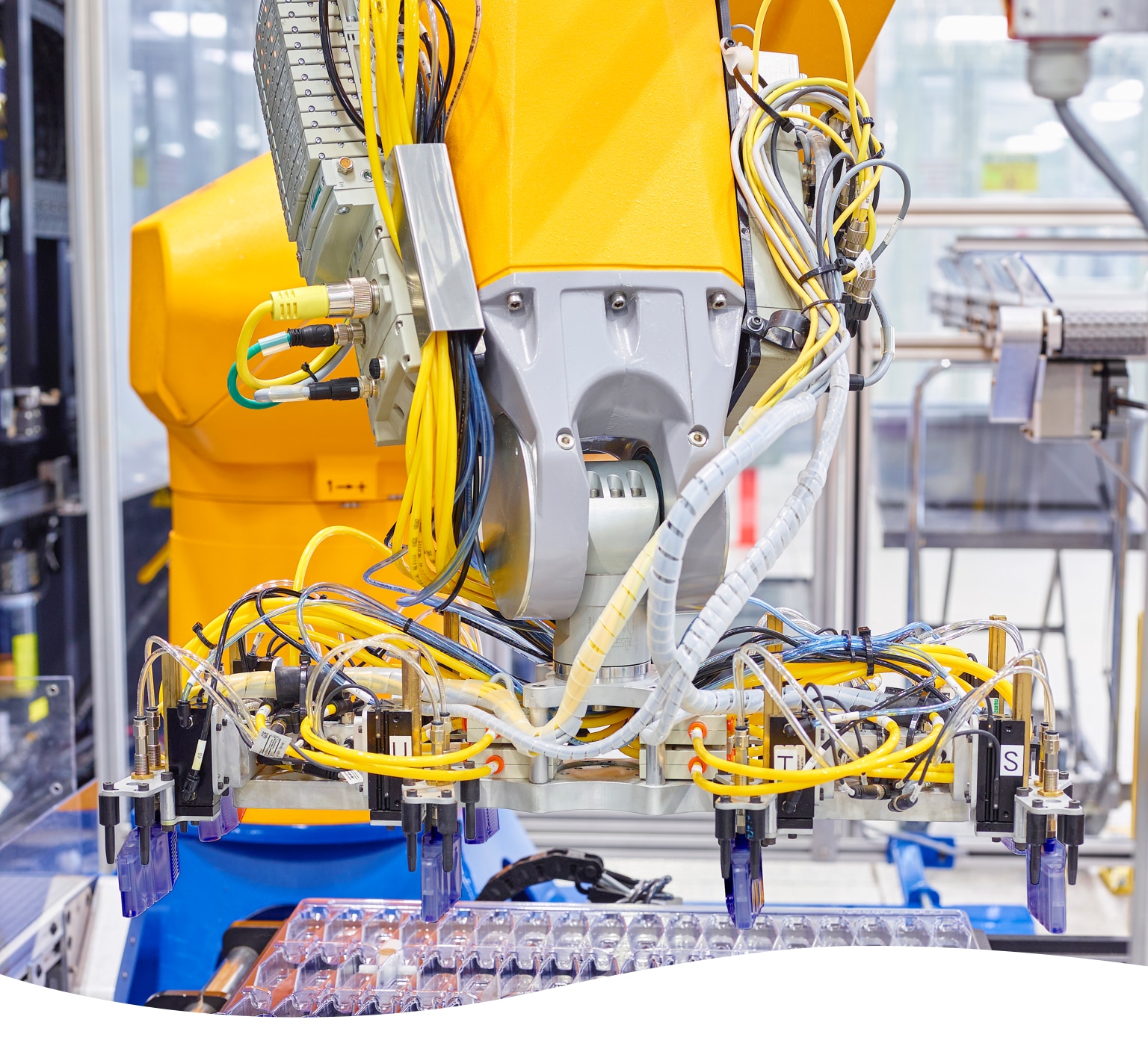

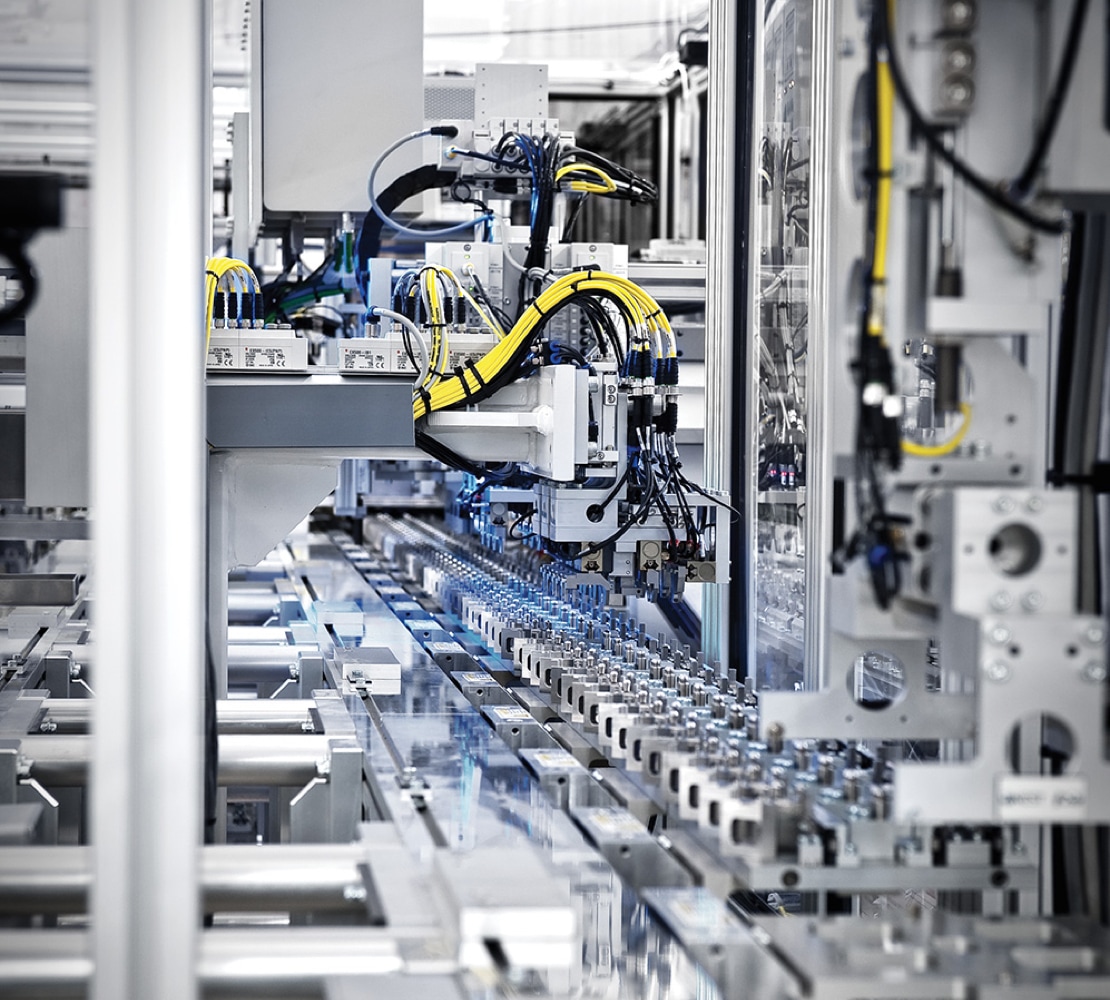

To achieve significant labor cost reductions, we implement extensive robotic integration in our manufacturing work cells. Our robots handle repetitive tasks like part removal, placement, and conveyance between process steps, eliminating human handling, human error, and contamination concerns.

We can also utilize one or more press-side operations to reduce or remove workflow steps. This type of automation includes downstream secondary processes that refine the workpiece, such as trimming, welding, and decorating.

For customers with high volume throughput needs, we offer application-specific, fully automated assembly and packaging solutions. Our automation technologies include continuous, indexing, and asynchronous motion assembly platforms featuring the latest mechanical, pneumatic, and robotic assembly innovations, with robust inspection and process control operations. In addition, we routinely design and operate high-speed, multicomponent manufacturing cells that produce assemblies and devices from resin to pack out without human intervention. Our expertise also includes the integration of multiple molding technologies into a single automated production line.

Besides assembly, we offer other valuable post-molding processes, including the following:

Accelerate your medical momentum with a single source for fully integrated manufacturing solutions.

CONTACT US