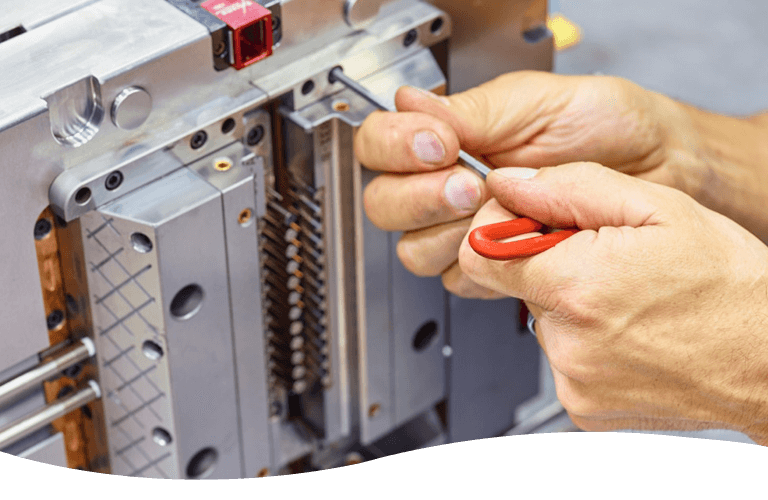

For seamless production continuity and supply chain assurance, our injection molding transfer tooling processes are meticulously developed to deliver reliability. We provide a comprehensive range of transfer tooling options tailored to the unique requirements of the medical manufacturing industry.

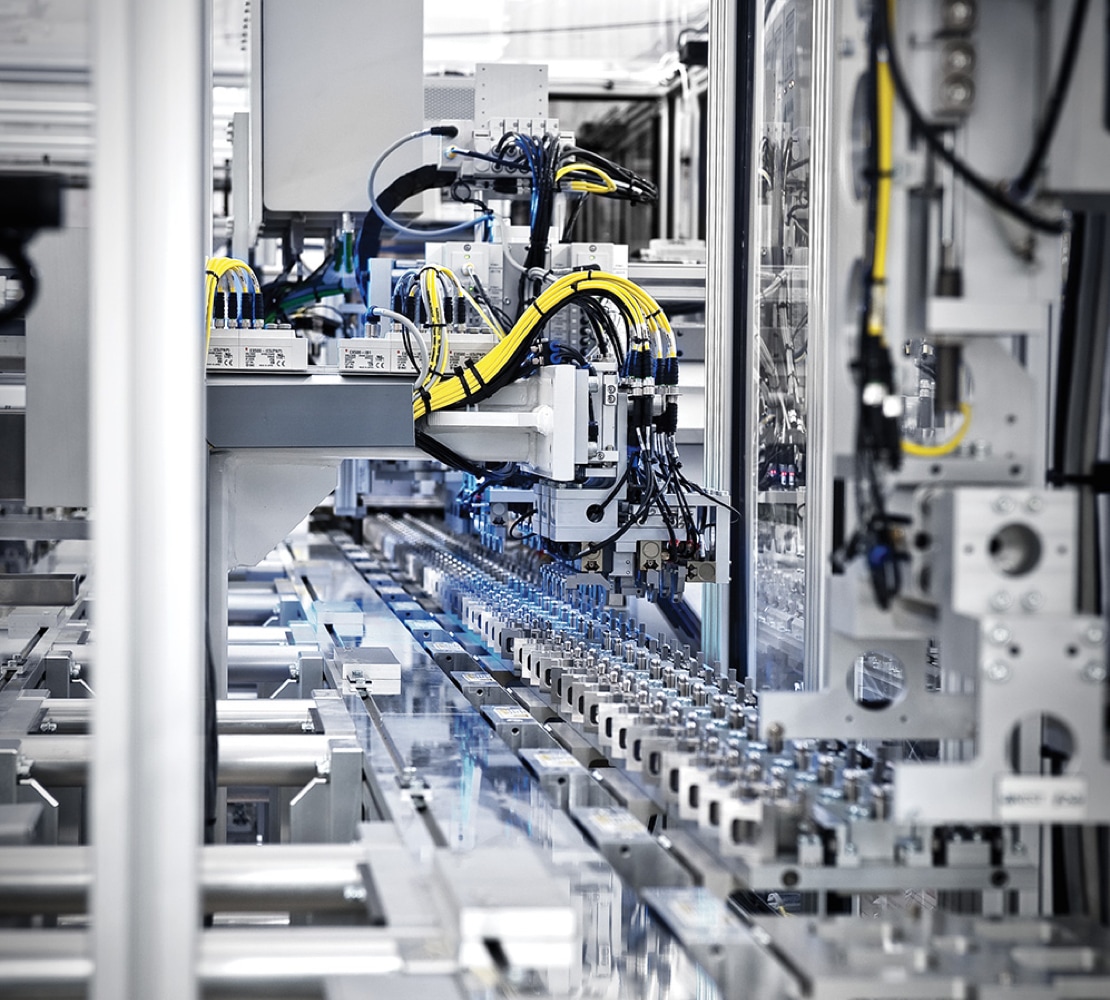

Contact UsAt Comar, we recognize the utmost significance of seamless tooling transfers in medical molding. Our Transfer Tooling Program is meticulously designed to cater to all your equipment transfer needs, regardless of its size. With a focus on eliminating any impact to supply chain disruptions, this comprehensive program aims to streamline processes and deliver exceptional results.

Our program is engineered to streamline and optimize the tooling transfer process, significantly reducing lead times. Experience quicker turnaround and get your manufacturing equipment up and running quickly.

We prioritize the quality and maintenance of your equipment, ensuring that every transfer is executed with precision and care. Throughout the process, we maintain the highest standards for your tools.

Achieve unmatched part-to-part consistency with our well-defined transfer procedures. Our rigorous approach guarantees that your production runs smoothly without any unexpected variations.

Our highly skilled team guides your tooling transfer process with meticulous action items guaranteed to make your switch to a new injection molding supply partner simple and seamless.

Having enough safety stock can bail out a faulty inventory management system in a pinch. Take the time needed to accurately access and order enough stock to ensure you always have an adequate supply for production requirements.

Practice due diligence with all executives and stakeholders involved through First Article Inspections, studying & solidifying processing requirements, validating supply efficiency with standardized statistical assessments, and continuing to refine and optimize through collaboration.

Incorporating as many key players into your new transfer tooling process as possible will help establish and maintain quality assurance, accountability, and superior communication across all teams involved.

Scheduling meetings in advance helps ensure that the necessary conversations regarding process efficiency, effectiveness, and optimization occur, and recommendations are made with the intent to implement improvements in the future.

Similar to Step 1, working together with your supply chain managers to guarantee enough product and raw materials on hand will prevent production delays and any lapse in project budget or pre-scheduled manufacturing agreements.

Generate all necessary inspection documentation, note all received assets and reports, identify and mitigate risks, and create clear agenda-based weekly meetings focused on your team’s commitment to executing and improving your newly-introduced transfer tooling process.

Benefit from the expertise of our trusted suppliers, which adds an extra layer of confidence to your processes. Partner with Comar today and experience the seamless execution of your tooling transfer, keeping your supply chain flowing effortlessly.

Download Full PDF