Closures

As a leading plastic closures manufacturer, Comar supplies a broad portfolio of caps, lids, and closure systems engineered for performance, safety, and regulatory compliance. Our closures fit a wide range of vials, jars, packer bottles, canisters, and containers used across pharmaceutical, nutraceutical, personal care, and household packaging applications.

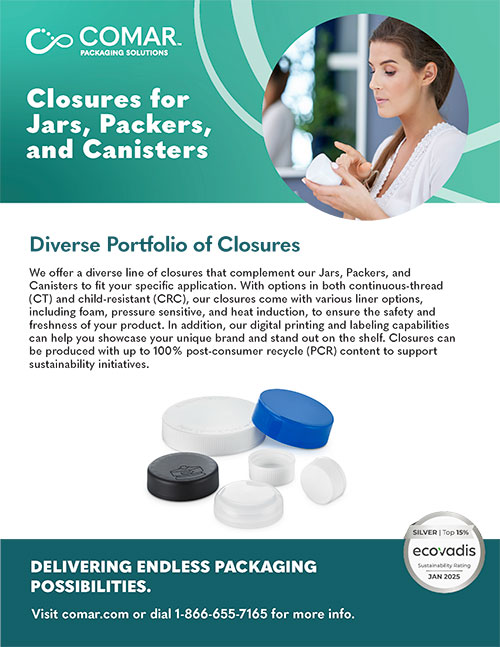

Choose from continuous-thread (CT), child-resistant (CR), hinged-dispensing, tamper-evident, or snap-top closures, each optimized for torque retention, seal integrity, liner adhesion, and compatibility with automated capping equipment. Options include foam, pressure-sensitive, linerless, and heat-induction liners to ensure product protection, leak prevention, and extended shelf life.

Continuous-Thread (CT) Closures

Our continuous-thread closures—often called CT caps—are precision-engineered for both plastic and glass containers and designed to meet industry neck finish standards (e.g., 38-400, 45-400) for interchangeability and capping efficiency. The threads form a continuous helical seal that ensures optimal torque performance and prevents leakage or product contamination.

This style of closure is widely used in pharmaceutical bottles, nutraceutical containers, and personal care jars due to its reliability, cost efficiency, and broad compatibility.

Features and Options:

- Sizes: 13-415 to 120-400, covering the most common neck finishes

- Styles: Ribbed, smooth, smooth high/tall, domed

- Stock Colors: White and black, with custom color matching available

- Lining Options: Unlined or lined (foam, pressure-sensitive, or heat induction) for optimal barrier performance and seal integrity

- Linerless Options: Available in 13 mm, 15 mm, and 18 mm with crab claw sealing for leak-proof performance and reduced packaging waste

- Decoration: In-house digital full-color printing and embossing for logos, dosage indicators, or branding

- Material: Polypropylene (PP)

- Sustainability: Manufactured with up to 100% post-consumer recycled (PCR) polypropylene for eco-friendly packaging solutions

Child-Resistant (CR) Closures

Child-Resistant closures are designed to require two motions (push-and-turn or squeeze-and-turn) to remove them from a container, making it challenging for a child to access the contents. They are mandated by law to protect children from exposure to potentially harmful products sold in the Rx and OTC pharmaceuticals, nutraceuticals, and cannabis industries. They are also frequently used as a safety precaution in the packaging of cosmetics, personal care products, and household chemicals. All of our CR closures are of the push-and-turn type.

Features and Options:

- Sizes: 28-400 to 89-400

- Push-and-turn Instructions: Text, pictorial, or blank for enhanced user compliance

- Colors: White and black, custom-matched options available

- Lining Options: Unlined or lined (foam, pressure-sensitive, or heat induction)

- Material: Polypropylene (PP)

- Sustainability: Available with up to 100% PCR content for sustainable closure solutions

QuarterLoc®

The QuarterLoc® Child-Resistant Closure combines child safety with manufacturing efficiency, featuring a one-piece design that reduces material use by 40%. The low-torque, quarter-turn mechanism improves thread alignment and closure torque repeatability, enhancing production throughput.

This innovative CRC design meets USP671 tight container integrity and supports induction sealing compatibility for validated, tamper-evident packaging.

Features & Options:

- Sizes: 53 mm and 63 mm, compatible with PET packer bottles with QL neck finishes

- Design: One-piece, single-material construction for cost-effective production

- Comfort: Soft ribs and audible clicks for tactile feedback

- Compliance: Meets USP671 container integrity standards

- Decoration: Optional engraved graphics or embossing

- Material: Polypropylene (PP) with PCR resin content

Hinged Dispensing / Tamper-Evident (HingeGard®)

Our HingeGard® closures deliver tamper-evident, hinged dispensing solutions for vitamins, nutritional supplements, OTC pharmaceuticals, and medical packaging. These closures are optimized for capping line compatibility, seal verification, and consumer convenience.

Features and Options:

- Sizes: 38 mm, 45 mm, and 53 mm for HingeGard® packer bottles

- Liners: Induction heat-sealable liners for pilfer resistance and oxygen/moisture barrier performance

- Colors: White and black with custom-matched options

- Customization: Embossed shells and branding available

- Material: Low-Density Polyethylene (LDPE) for impact resistance and flexibility

Wipe Canister Lids

Our wipe canister lids are engineered for household, institutional, and healthcare cleaning applications, ensuring seal retention, chemical resistance, and moisture control. Designed for compatibility with standard neck finishes, they support automated lid application for high-volume production lines.

Features and Options:

- Sizes: 80 mm, 105 mm, 120 mm

- Seal Types: Single, double, or triple-seal configurations for enhanced evaporation control

- Colors: White, yellow, blue, green with custom options

- Designs: Flat or dome styles with various well diameters for material threading efficiency

- Decoration: Custom logo or branding inserts available

- Material: Polypropylene (PP)

- Sustainability: Available with PCR resin for eco-conscious manufacturing

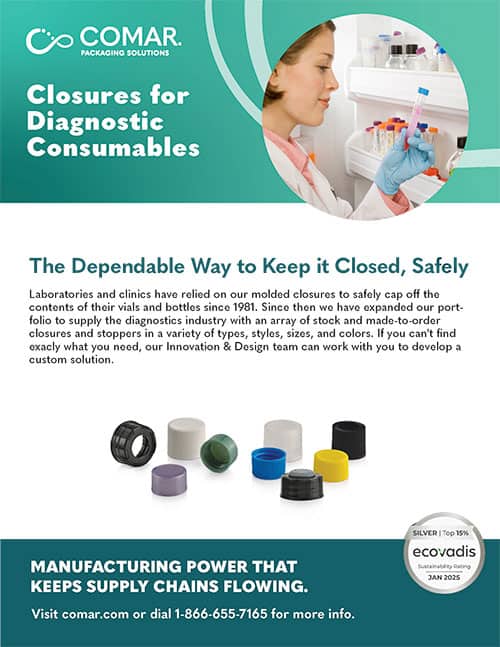

Dropper Tip Caps

Our dropper tip caps provide secure, precise closure solutions for pharmaceutical, diagnostics, and personal care applications. Designed for continuous-thread compatibility, these caps ensure tight seal integrity and drop control accuracy.

Features & Options:

Standard Dropper Tip Caps

- Finish Sizes: 8-425 to 15-415 (industry-standard neck finishes)

- Style: Ribbed sides with a continuous thread for ergonomic grip

- Colors: White, Red, Yellow, Green, Blue, Orange, Black

- Materials: Polypropylene (PP) or Polystyrene (PS) for chemical compatibility and clarity

- Applications: Ideal for liquid dosing, diagnostic reagents, essential oils, and cosmetic serums

SecureCap® Child-Resistant/Senior-Friendly Dropper Tip Caps

The SecureCap® series combines child-resistant packaging with senior-friendly design, balancing safety and usability for pharmaceutical and nutraceutical liquids. Each closure meets CPSC, USP, and MVTR (Moisture Vapor Transmission Rate) requirements for validated barrier protection.

- Style: Ribbed sides, continuous thread

- Closure Finish: 15-415 and 18-410

- Standard Colors: White, Red, Yellow, Green, Blue, Orange, and Black.

- Material: PP (polypropylene)

- Meets CPSC and USP standards:

- Consumer Product Safety Commission (CPSC) Title 16 Code of Federal Regulations (CFR) 1700.2.

- USP 27 Extractables Testing

- USP 27 Light Transmission Testing

- USP 32 Container Performance Testing for Moisture Vapor Transmission Rates (MVTR)

Oral Syringe Tip Caps

Our oral syringe tip caps are designed for liquid dosing syringes used in pediatric and pharmaceutical packaging, ensuring a secure snap-fit seal and maintaining dose accuracy during storage and transport.

- Snap-on standard or self-righting tip cap designs

- Maintains sterility and cleanliness of syringe tips

- Standard Colors: White, blue, natural

- Compatible with ISO-standard syringe fittings

Custom Solutions

Looking for a custom cap or closure manufacturer? Our Innovation and Design Team collaborates with packaging engineers and brand managers to create custom-engineered packaging solutions. Whether you need a proprietary closure design, sustainable packaging material integration, or specialized regulatory compliance, our experts deliver precise, manufacturable results.